Contemporary Case Study Projects

Reagan National Airport, Washington, D.C.

Reagan National Airport in Washington, D.C., designed by Cesar Pelli Architect, uses Architecturally Exposed Structural Steel to create the character of the airport. The choice of wide flange sections and other angular types that have been welded together to form tree like structures creates a very different feeling than many AESS applications that choose to use round HSS members. The design intentions allow for expressive bolting that becomes the aesthetic of the space. This changes the detailing practices for the connections.

|

Overall view of one of the steel trees that form the primary structure of the airport. The faceted, rather than bent, appearance of the trees is complemented by the use of wide flange and angle type members. |

|

The end conditon of the truss tree where it meets the outside glazed wall must accommodate horizontal framing members. Here you see the angled connection of the end beam - a wide flange section - which uses a simple bolted connection to attach to the tree column. The weld on the web of the end beam is visible where two wide flange sections have been connected to make the geometry. Looking into the recesses of the column it can be seen that the branches of the tree are fabricated from wide flange sections. The flange has been removed to expose the web member, which is welded to the column. |

|

The curved trusses have been fabricated from wide flange and angle sections. Rather than actually curving the members, the trusses have been faceted. Straight sections for the top and bottoom chord have been cut and welded, with the change of direction happening at the panel point of the truss. Welded connections have been used rather than bolts to provide a less cluttered appearance given the complexity of the members themselves. |

|

This is a flange-plated moment connection to the column. As such, it is transferring shear through the 5 bolt shear tab and the flange plates are transferring the design moment. The flange plates are the principal connection here rather than reinforcement for the apparently lightly loaded shear tab. This is a cruciform column, with the plates in the column being continuity plates (transverse stiffener plates) that provide continuity for the moment transfer across the column. They have to align with the beam flanges as closely as possible to maintain the load path and prevent failing the column flanges in bending. |

|

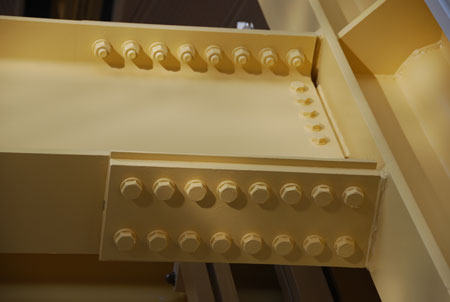

The project makes use of bolted connections to create its aesthetic. Here you can see that the bolts have been carefully positioned and the bolt heads all located on the outer face for uniformity. This project uses hex head bolts. These require access to both sides of the connection for tightening. A shim plate is visible at the base, however it has been painted "out" so is not noticeable. Shim plates are used where alignment is not quite perfect. In AESS structures tolerances are normally half standard - so very tight. |

|

The vertical wind brace trusses are created using round HSS members for the outer chords and flat plat members as the web pieces. The entire structure is welded for a clean appearance. Here you can see the connection of the wind brace to the aluminum curtain wall system. |

|

The base of the vertical wind brace behind the glazing is connected to the floor via a simple pin connection. The single plate at the base of the brace is simply cut and welded into the vertical HSS members of the brace. This plate slots between a pair of plates. The connector uses a cotter pin rather than a bolt with nut. |